We recently used our ESAB Oxy fuel gas machine to process these 60mm thick S355J2W weathering steel profiles, which are over 16mtrs long and weigh 7000kgs each.

These will be fabricated into a bridge and be part of the TransPennine Route Upgrade.

Murray Steel Products has an extensive in-house ISO 9001 and CE Execution Class 4 accredited processing operation, which includes high-definition profiling, cutting and drilling.

Our team produce a wide range of bespoke steel profiles and products for customers, some of which are showcased below.

Click here for more information about our processing capabilities.

We recently used our ESAB Oxy fuel gas machine to process these 60mm thick S355J2W weathering steel profiles, which are over 16mtrs long and weigh 7000kgs each.

These will be fabricated into a bridge and be part of the TransPennine Route Upgrade.

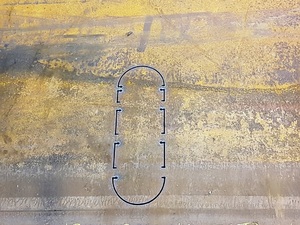

A client working within the waste and decarbonising sector recently asked us to produce a part but unfortunately didn’t have any CAD drawings. With only the original part to work with, our CAD team produced a technical drawing including additional customer amendments for their approval.

Click the image to see the original part supplied, followed by our new CAD drawing and the completed order.

We used 20mm S275JR steel for the job which was drilled with Ø18 & Ø50 holes and was complemented with some 5mm thick S275JR steel rings.

Our Esab HD plasma cutting machine was recently in action cutting these 15mm S355J2 parts for a client supplying the offshore sector.

We included all slots and added 5mm green onto the 1500mm o/d for further machining at the customer’s request.

We recently processed these 30mm thick mild steel profiles on our Tecoi THOR machine, adding drilled, M24 tapped and countersunk holes to take M24 bolts.

Any loss in fabrication time can be costly. That’s why we offer fabrication mark etching as an additional steel processing service.

For added traceability, we can also add etched part and job numbers which can withstand the shotblasting or galvanising process.

With two THOR plate processing stations by Tecoi running on a 21 mtr bed, we can make light work of heavy fittings, at double the speed.

These 60mm S355J2 connecting steel plates used within the construction sector were drilled with Ø25 holes. The THOR can drill an Ø80 hole in a single pass on S355J2 material.

An order for a customer in the water industry, consisting of Prime S275 25mm & 35mm gauge profiled rings.

One face has been machined to very tight tolerances, the other skimmed, with 32 50mm diameter drilled holes per piece, each to a tolerance of +/- 0.2mm.

This 10mm gauge chequer-plate is part of an ongoing piece of work, and will soon be delivered to a telecommunications project in West Africa.

Including 26mm diameter countersinking with 14mm profiled holes, these pieces were profiled to size using our Hypertherm XPR300 Plasma cutting system.

We recently cut 100mm S355J2 profiled plate for one of our customers in the subsea and offshore industry.

They required our plate processing services for their clump weights, a critical component for subsea structures, and we were more than happy to accept the challenge!

We manufactured and supplied these S355J2+N plasma and gas cut profiles for an agricultural client.

This piece of work included plate gauges from 25mm to 80mm, with profiled slots and 25mm diameter holes drilled to a tolerance of +/- 0.2mm.

We manufactured and supplied these steel profiles for one of our clients in the offshore sector. The project consisted of 8 prime S355G10+N profiles, each at a gauge of 110mm.

Oxy-Gas profiled to a diameter of 800mm at a tight tolerance, each piece weighs over 300 kilos, bringing the set to over 2.4 tonnes in total.

This project included Z35-tested prime S355J2 and S460NL steel plate, with dimensions up to 3.4m x 2m, and gauges up to 150mm.

Weighing in at 50 tonnes overall, this order included profiles with 33mm & 39mm diameter holes, drilled to a tolerance of +/-0.2mm. Additional processing included edge chamfering and countersunk holes.

A selection of heavy architectural work we have completed this week. These prime 10mm thick S275JR, high-definition plasma cut profiles contain an array of profiled slots and holes at tolerances of +/-2mm. Spanning up to 7.5m x 3m in size, there are 396 different pieces weighing in at 20 tonnes in total.

These 25mm gauge flanges have been plasma cut to dimensions of 1.1mx1m and 1600mm x 1100mm. We drilled 528 26mm diameter holes for this project, each with a tolerance of +/- 0.2mm.

This order also consisted of 35mm flame-cut profiles with drilled and tapped holes, weighing in at a total of 12 tonnes.